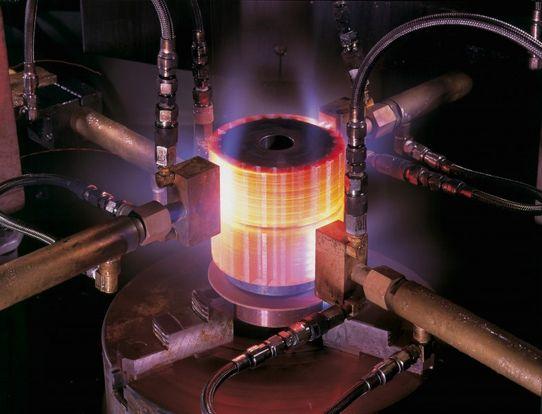

SPECIAL PROCESSES

Integral to our precision machining service, we have developed deep expertise in working with the right special process partners over the last 22 years

Wave Mechanics works with partners that are accredited with NADCAP and AS9100 certifications for a wide variety of special processes. Long term relationships with these partners allow us to work with them in a collaborative manner, reducing lead times and ensuring the quality of finished parts.

If you would like to learn more about the many ways in which Wave Mechanics can meet all your precision manufacturing requirements, contact us today. We will also be happy to provide a no-obligation quote for any of our precision manufacturing services. We look forward to helping you.

Contact Us